Beijing Aurasky Electronics Co., Ltd.

(formerly Beijing Sevenstar Flow Co., Ltd.)

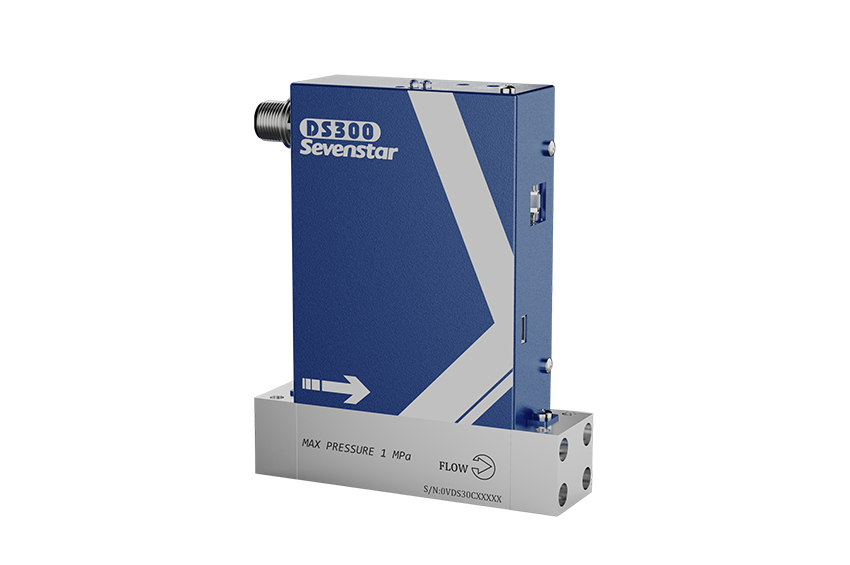

Beijing Aurasky Electronics Co., Ltd. (AURASKY), formerly known as Beijing Sevenstar Flow Co., Ltd., builds upon its more than four decades of experience and technology in flow measurement and control. By integrating professional technical expertise and innovative capabilities in radio frequency, wafer transfer and other related fields, AURASKY is dedicated to providing solutions to precision control components and comprehensive project for users in five major sectors: semiconductor, clean energy, specialty industries, life sciences, and scientific research.

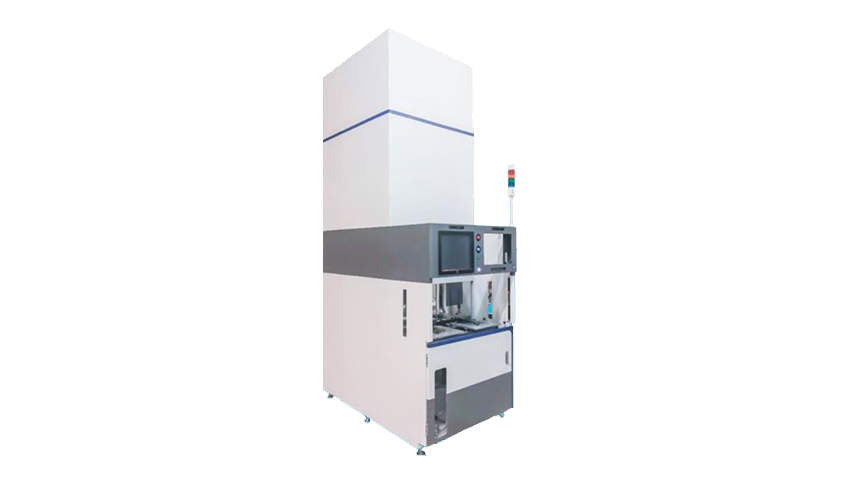

AURASKY adheres to the philosophy of "continuous innovation oriented by customer needs". By deeply studying customer demands, respecting science, focusing on technology, and pursuing continuous innovation, AURASKY has developed a series of products including flow measurement and control, vacuum measurement and control, gas panel, RF generators, ESC DC power supplies, magnetic fluid sealing device, and wafer transfer systems. AURASKY has established four major R&D and production bases, with its marketing and service system covering major countries and regions in Europe, America, and Asia.

As a pioneer in precision control, AURASKY takes continuous innovation as its responsibility, breaks through its own boundaries, actively explores the frontier technology, and contributes AURASKY value to its global partners, based on win-win cooperation.

Chairman's address

Components Inspire Great Innovations

The current era is full of challenges and opportunities, with waves of technological advancements surging forward at an unprecedented pace. Technologies such as Integrated Circuits (IC), Artificial Intelligence (AI), 5G Communications, the Internet of Things (IoT), Autonomous Driving, and Renewable Energy shine like bright stars, illuminating the path forward for humanity. Each subtle technological leap contains a majestic force that propels the giant ship of society to break the waves.

Just as AURASKY, with extraordinary insight and relentless dedication, has deeply cultivated the research and manufacturing of high-end precision components, transforming every seemingly insignificant "small component" into a vibrant cell pulsating with the rhythm of the times. These components support key fields such as semiconductor, clean energy, specialty industries, life sciences and scientific research, laying a solid foundation and injecting endless momentum into the wave of global innovation and sustainable development.

AURASKY takes the development of high-end precision parts as its own responsibility. Based on the inheritance of more than 40 years of experience and technology in flow measurement and

control, AURASKY is brave to explore and innovate, integrating and incorporating the advantages of specialized technology and innovation capabilities in radio frequency, wafer transfer, etc., and is striving to build an advanced platform for the high-end precision parts industry in China.

Looking ahead, as humanity accelerates its pace in exploring the unknown and pursuing excellence, key component technologies will continue to play a crucial role. AURASKY will keep pace with the times, continuously enhance its independent innovation capabilities, and shine brightly in the field of high-end precision components. AURASKY is committed to contributing its wisdom and strength to humanity's "great innovations" for the future of development.

Chairman of AURASKY : Liu Lijian

Aurasky Global