-

Fluid Control ProductsFluid control utilizes various control modules to accurately control key specifications such as fluid flow, pressure and vacuum to meet the specific process needs in the industrial field. With more than 40-Year development on the field of fluid control, AURASKY has developed a series of products such as gas mass flow controllers, pressure controllers,capacitive diaphragm gauges, vacuum switches, pressure sensors, differential pressure pauges, liquid pressure transducers, mixing vaporizers and gas panels. These products play a vital role in many fields such as IC, photovoltaics, vacuum coating and scientific research.

-

Gas Flow Measurement & Control

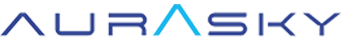

Gas Flow Measurement & ControlGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.-

Semiconductor

-

Clean Energy

-

Vacuum Industries

-

Life Sciences

-

Scientific Research

-

-

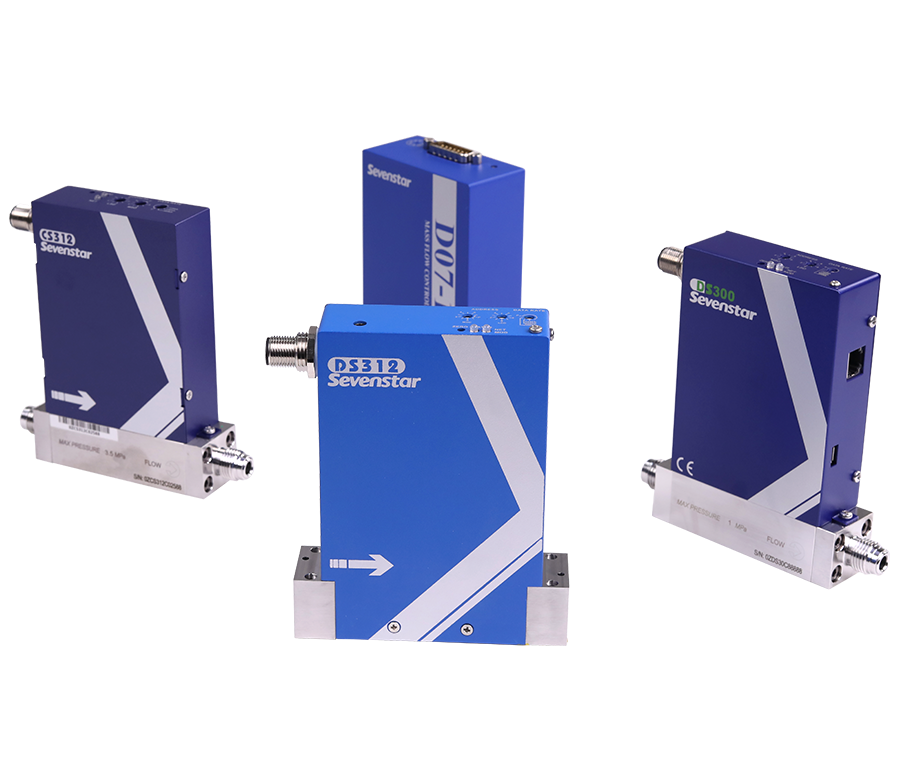

Vacuum Measurement & ControlAURASKY based on its advanced R&D experience in gas mass flow controllers,has continuously expanded its product portfolio to include precision control components such as gas pressure controllers, capacitive diaphragm gauges, pressure transmitters, vacuum pressure switches, butterfly valves, and pendulum valves. These products feature high accuracy, high stability, fast response, and high repeatability, providing stable pressure control solutions for high-end manufacturing fields to ensure process stability and consistency.

-

Semiconductor

-

Clean Energy

-

Vacuum Industries

-

Life Sciences

-

Scientific Research

-

-

Liquid Flow Measurement & Control

Liquid Flow Measurement & ControlAURASKY offers a comprehensive range of liquid control products, covering liquid pressure measurement, flow rate monitoring, and liquid level sensing. Our portfolio includes liquid pressure transducer,liquid heaters, liquid flow controllers, mixing vaporizer, and steam filters. Boasting high accuracy, exceptional stability, rapid response, and excellent repeatability, these solutions deliver reliable liquid control for the high-end integrated circuit industry.-

Semiconductor

-

-

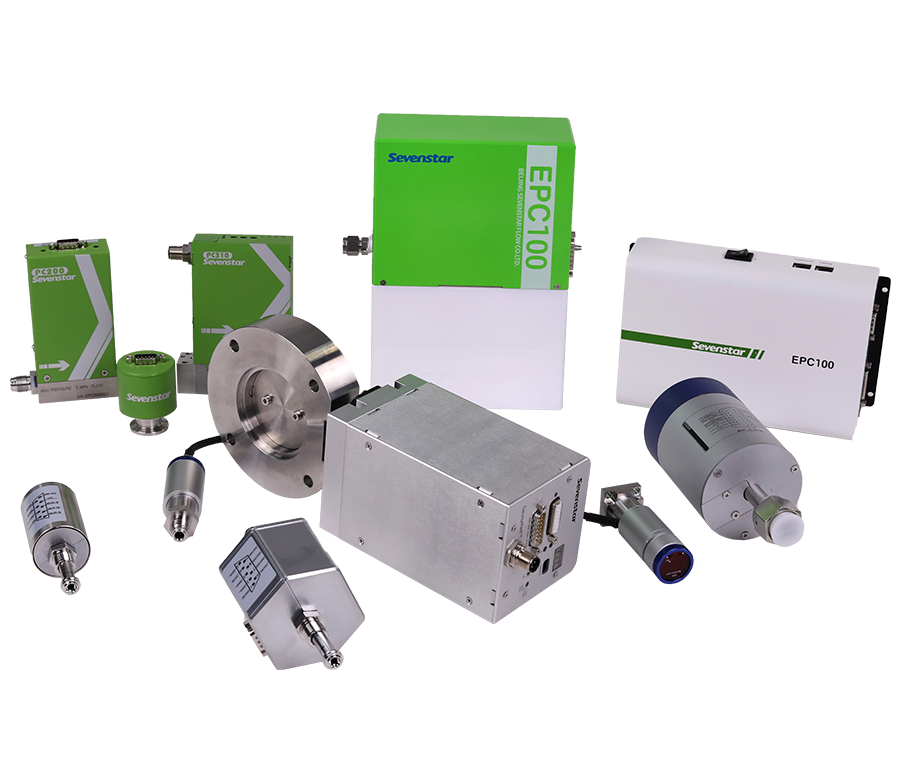

Gas PanelGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.

-

Semiconductor

-

Clean Energy

-

Specialty Industries

-

Life Sciences

-

Scientific Research

-

-

-

RF Control ProductsPlasma control is typically achieved by adjusting the type and concentration of the activating gas, and controlling the radio frequency power and gas pressure to precisely control plasma parameters, including plasma density, temperature, and composition. Huacheng Electronics has devoted itself to the research of plasma control, and has mastered ICP (Inductively Coupled Plasma) and CCP (Capacitively Coupled Plasma) technologies. Currently, the mass production of pulse radio frequency power supplies has been achieved, and multiple single-frequency/dual-frequency digital matchers have successfully passed 14nm production line verification and achieved mass production. ESC DC power supplies have been successfully applied in etching and thin film deposition equipment in the integrated circuit field.

-

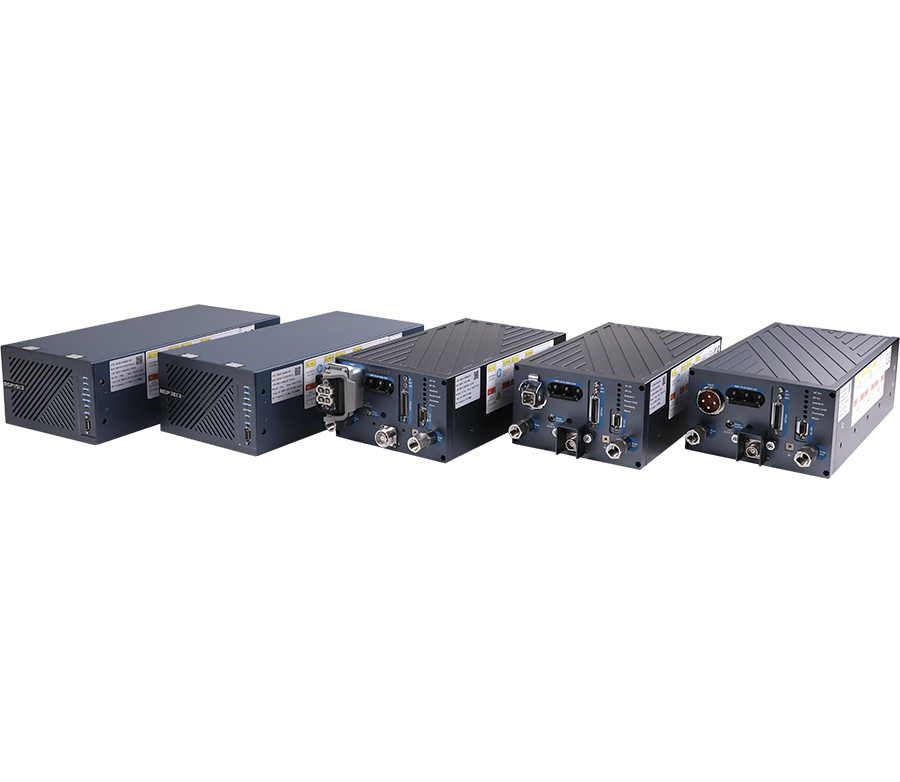

RF GeneratorThe RF Generator is a power supply device capable of generating sinusoidal waves at specific frequencies. Its core function involves converting facility-level electrical energy into high-frequency electrical energy through integrated circuit systems, including DC power supply units, RF power units, measurement modules, control modules, and communication interfaces. The output power and frequency can be accurately controlled.

-

Semiconductor

-

-

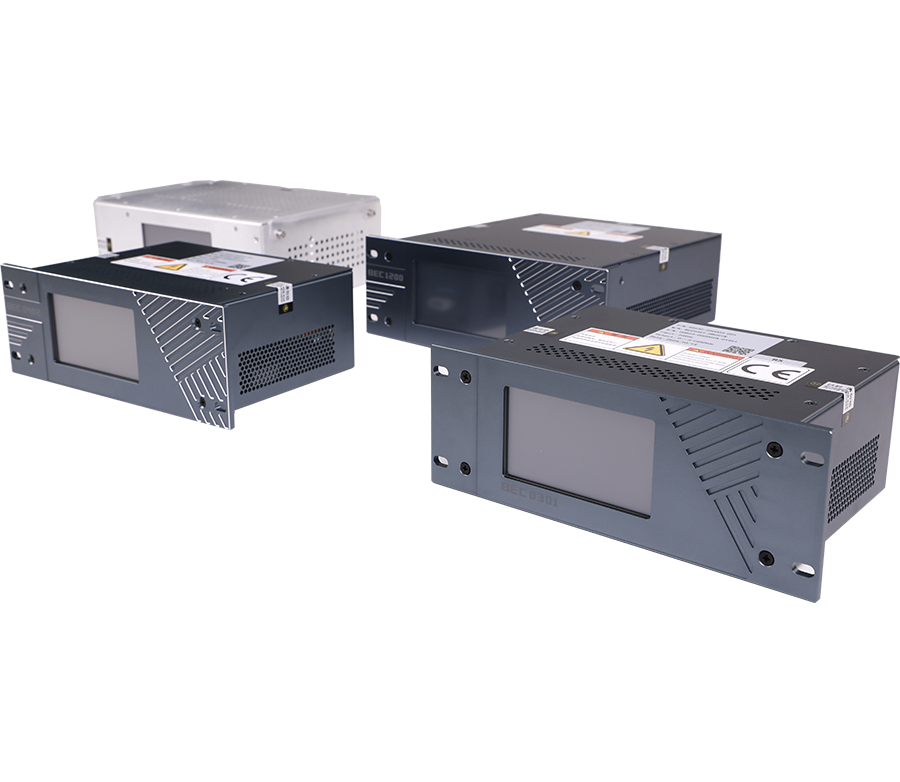

MatchThe Match is designed to align the impedance between the RF Generator and the plasma chamber, ensuring maximum RF power transfer to the chamber. It can be customized for specific application scenarios, delivering rapid, accurate, and stable impedance matching across Variable frequencies and power ranges.

-

Semiconductor

-

-

DC / LF Power SupplyThe DC/LF Power Supply is a device that converts alternating current (AC) or other forms of energy into direct current (DC) or low-frequency (LF) electrical energy through energy conversion mechanisms. The ESC DC Power Supply is a high-voltage product specifically designed for semiconductor applications. It is compatible with unipolar/bipolar and Coulomb-type/- JR-type electrostatic chucks (ESC), providing a stable electrostatic field for wafer adsorption. The RPS (Remote Plasma Source) is a high-stability, low-frequency power supply dedicated to semiconductor applications. It is widely used in cleaning process equipment for oxides, nitrides, and other materials, ensuring reliable plasma stability during critical manufacturing steps.

-

Semiconductor

-

-

-

Wafer Transfer ProductsMotion control achieves reliable wafer transfer and storage through an intelligent motion control system. High yield control is realized through excellent capacity management, particle control, vibration suppression, and motion path planning technologies. AURASKY's R&D and manufactured wafer transfer products achieve stable atmospheric and vacuum transfer control for single wafers and batches. Currently, the wafer cassette transfer and storage systems, wafer transfer systems, front-end equipment modules, and wafer transfer platforms developed and manufactured have achieved mass production and delivery at multiple clients in the semiconductor and related industries.

-

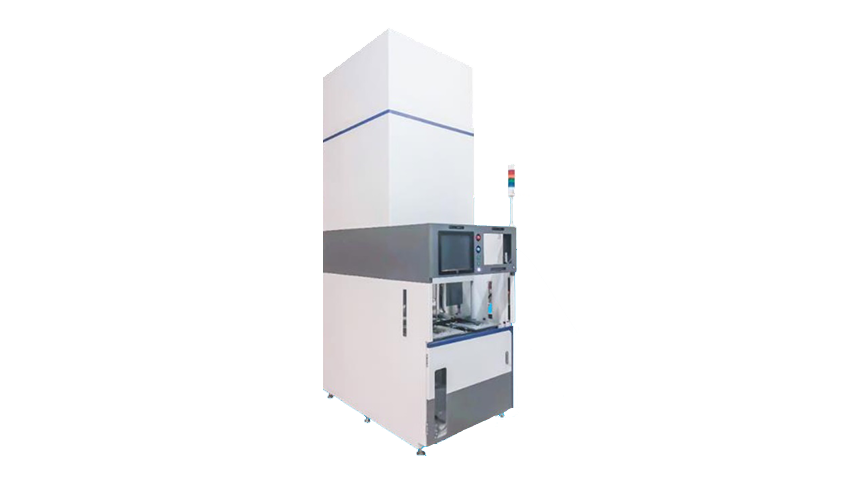

Wafer box transfer and storage system Stocker

Wafer box transfer and storage system StockerThe stocker equipment for wafer box transfer and storage system is mainly used in the semiconductor field, acting as a buffer for wafer boxes (FOUP) in the vertical furnace production process. The stocker equipment effectively solves the problem of mismatched supply and cycle time between the vertical furnace process and upstream and downstream processes, and it also realizes the fully automatic opening and closing function of wafer boxes (FOUP), avoiding the impact of manual intervention, ensuring the clean environment of the vertical furnace production process, and improving product quality.-

Semiconductor

-

-

Wafer Transfer System (WTS)The system interacts with the customer's OHT system to achieve Foup input and output, uses a FOUP robotic arm to transfer and store Foups between different process stages, uses an internal Loadport to open and map Foups, uses WTS to transfer, combine, and separate wafers, uses mapping at three locations to confirm wafer status and compare data, uses a fixed BF to buffer 50P wafers, and uses PTZ to hand off to the cleaning robot. The top EFU maintains a micro-clean environment for the equipment, and the top ion bar removes electrostatic residue from the transport path.

-

Semiconductor

-

-

Equipment Front-End Module (EFEM)

Equipment Front-End Module (EFEM)EFEM stands for Equipment Front End Module. EFEM equipment seamlessly connects with various semiconductor process equipment (etching, PVD, CVD, cleaning equipment, etc.), ensuring automated wafer transfer and efficient wafer management in a clean environment. EFEM equipment has multiple interlocks to ensure the safety of personnel and equipment during wafer transfer.-

Semiconductor

-

-

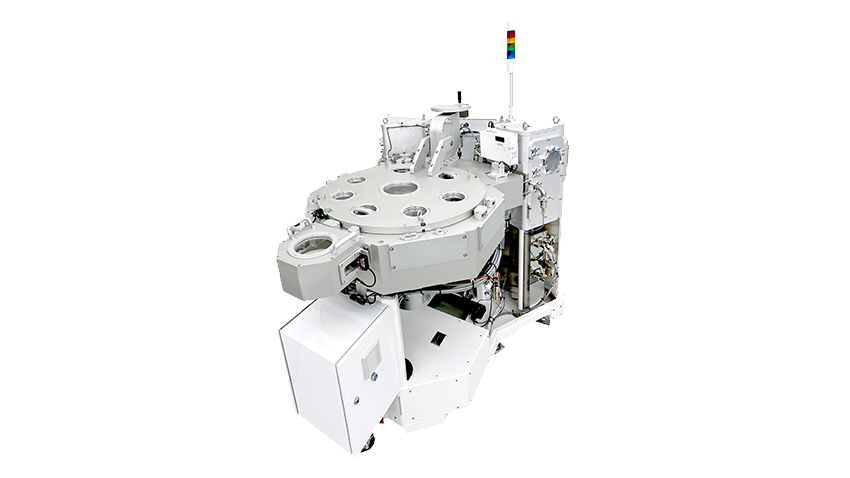

Wafer Transfer Module (WTM)Wafer transfer platforms are an indispensable part of semiconductor process equipment. They primarily automate wafer transfer between different modules in cleanroom and vacuum environments. These platforms can quickly switch between atmospheric and vacuum states to meet system process requirements. This equipment is typically customized to meet customer process needs.

-

Semiconductor

-

-

-

Fluid Control ProductsFluid Control ProductsFluid control utilizes various control modules to accurately control key specifications such as fluid flow, pressure and vacuum to meet the specific process needs in the industrial field. With more than 40-Year development on the field of fluid control, AURASKY has developed a series of products such as gas mass flow controllers, pressure controllers,capacitive diaphragm gauges, vacuum switches, pressure sensors, differential pressure pauges, liquid pressure transducers, mixing vaporizers and gas panels. These products play a vital role in many fields such as IC, photovoltaics, vacuum coating and scientific research.

-

Gas Flow Measurement & Control

Gas Flow Measurement & ControlGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.

Gas Flow Measurement & ControlGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.-

SemiconductorSemiconductor

-

Clean EnergyClean Energy

-

Vacuum IndustriesVacuum Industries

-

Life SciencesLife Sciences

-

Scientific ResearchScientific Research

-

-

Vacuum Measurement & Control

Vacuum Measurement & ControlAURASKY based on its advanced R&D experience in gas mass flow controllers,has continuously expanded its product portfolio to include precision control components such as gas pressure controllers, capacitive diaphragm gauges, pressure transmitters, vacuum pressure switches, butterfly valves, and pendulum valves. These products feature high accuracy, high stability, fast response, and high repeatability, providing stable pressure control solutions for high-end manufacturing fields to ensure process stability and consistency.

Vacuum Measurement & ControlAURASKY based on its advanced R&D experience in gas mass flow controllers,has continuously expanded its product portfolio to include precision control components such as gas pressure controllers, capacitive diaphragm gauges, pressure transmitters, vacuum pressure switches, butterfly valves, and pendulum valves. These products feature high accuracy, high stability, fast response, and high repeatability, providing stable pressure control solutions for high-end manufacturing fields to ensure process stability and consistency.-

SemiconductorSemiconductor

-

Clean EnergyClean Energy

-

Vacuum IndustriesVacuum Industries

-

Life SciencesLife Sciences

-

Scientific ResearchScientific Research

-

-

Liquid Flow Measurement & Control

Liquid Flow Measurement & ControlAURASKY offers a comprehensive range of liquid control products, covering liquid pressure measurement, flow rate monitoring, and liquid level sensing. Our portfolio includes liquid pressure transducer,liquid heaters, liquid flow controllers, mixing vaporizer, and steam filters. Boasting high accuracy, exceptional stability, rapid response, and excellent repeatability, these solutions deliver reliable liquid control for the high-end integrated circuit industry.

Liquid Flow Measurement & ControlAURASKY offers a comprehensive range of liquid control products, covering liquid pressure measurement, flow rate monitoring, and liquid level sensing. Our portfolio includes liquid pressure transducer,liquid heaters, liquid flow controllers, mixing vaporizer, and steam filters. Boasting high accuracy, exceptional stability, rapid response, and excellent repeatability, these solutions deliver reliable liquid control for the high-end integrated circuit industry.-

SemiconductorSemiconductor

-

-

Gas Panel

Gas PanelGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.

Gas PanelGas Mass Flow Controller (MFC) is a device used for precise measurement and control of gas flow. Since developing its first analog gas mass flow controller in 1979, AURASKY has continuously iterated and innovated, optimizing performance to successively launch thermal based digital gas mass flow controllers and pressure based digital gas mass flow controllers. These products offer advantages such as high precision, high reliability, low zero drift, corrosion resistance and rapid response. Currently, the product range encompasses over 100 types, making them one of the indispensable core components in high-end manufacturing fields.-

SemiconductorSemiconductor

-

Clean EnergyClean Energy

-

Specialty IndustriesSpecialty Industries

-

Life SciencesLife Sciences

-

Scientific ResearchScientific Research

-

-

-

RF Control ProductsRF Control ProductsPlasma control is typically achieved by adjusting the type and concentration of the activating gas, and controlling the radio frequency power and gas pressure to precisely control plasma parameters, including plasma density, temperature, and composition. Huacheng Electronics has devoted itself to the research of plasma control, and has mastered ICP (Inductively Coupled Plasma) and CCP (Capacitively Coupled Plasma) technologies. Currently, the mass production of pulse radio frequency power supplies has been achieved, and multiple single-frequency/dual-frequency digital matchers have successfully passed 14nm production line verification and achieved mass production. ESC DC power supplies have been successfully applied in etching and thin film deposition equipment in the integrated circuit field.

-

RF Generator

RF GeneratorThe RF Generator is a power supply device capable of generating sinusoidal waves at specific frequencies. Its core function involves converting facility-level electrical energy into high-frequency electrical energy through integrated circuit systems, including DC power supply units, RF power units, measurement modules, control modules, and communication interfaces. The output power and frequency can be accurately controlled.

RF GeneratorThe RF Generator is a power supply device capable of generating sinusoidal waves at specific frequencies. Its core function involves converting facility-level electrical energy into high-frequency electrical energy through integrated circuit systems, including DC power supply units, RF power units, measurement modules, control modules, and communication interfaces. The output power and frequency can be accurately controlled.-

SemiconductorSemiconductor

-

-

Match

MatchThe Match is designed to align the impedance between the RF Generator and the plasma chamber, ensuring maximum RF power transfer to the chamber. It can be customized for specific application scenarios, delivering rapid, accurate, and stable impedance matching across Variable frequencies and power ranges.

MatchThe Match is designed to align the impedance between the RF Generator and the plasma chamber, ensuring maximum RF power transfer to the chamber. It can be customized for specific application scenarios, delivering rapid, accurate, and stable impedance matching across Variable frequencies and power ranges.-

SemiconductorSemiconductor

-

-

DC / LF Power Supply

DC / LF Power SupplyThe DC/LF Power Supply is a device that converts alternating current (AC) or other forms of energy into direct current (DC) or low-frequency (LF) electrical energy through energy conversion mechanisms. The ESC DC Power Supply is a high-voltage product specifically designed for semiconductor applications. It is compatible with unipolar/bipolar and Coulomb-type/- JR-type electrostatic chucks (ESC), providing a stable electrostatic field for wafer adsorption. The RPS (Remote Plasma Source) is a high-stability, low-frequency power supply dedicated to semiconductor applications. It is widely used in cleaning process equipment for oxides, nitrides, and other materials, ensuring reliable plasma stability during critical manufacturing steps.

DC / LF Power SupplyThe DC/LF Power Supply is a device that converts alternating current (AC) or other forms of energy into direct current (DC) or low-frequency (LF) electrical energy through energy conversion mechanisms. The ESC DC Power Supply is a high-voltage product specifically designed for semiconductor applications. It is compatible with unipolar/bipolar and Coulomb-type/- JR-type electrostatic chucks (ESC), providing a stable electrostatic field for wafer adsorption. The RPS (Remote Plasma Source) is a high-stability, low-frequency power supply dedicated to semiconductor applications. It is widely used in cleaning process equipment for oxides, nitrides, and other materials, ensuring reliable plasma stability during critical manufacturing steps.-

SemiconductorSemiconductor

-

-

-

Wafer Transfer ProductsWafer Transfer ProductsMotion control achieves reliable wafer transfer and storage through an intelligent motion control system. High yield control is realized through excellent capacity management, particle control, vibration suppression, and motion path planning technologies. AURASKY's R&D and manufactured wafer transfer products achieve stable atmospheric and vacuum transfer control for single wafers and batches. Currently, the wafer cassette transfer and storage systems, wafer transfer systems, front-end equipment modules, and wafer transfer platforms developed and manufactured have achieved mass production and delivery at multiple clients in the semiconductor and related industries.

-

Wafer box transfer and storage system Stocker

Wafer box transfer and storage system StockerThe stocker equipment for wafer box transfer and storage system is mainly used in the semiconductor field, acting as a buffer for wafer boxes (FOUP) in the vertical furnace production process. The stocker equipment effectively solves the problem of mismatched supply and cycle time between the vertical furnace process and upstream and downstream processes, and it also realizes the fully automatic opening and closing function of wafer boxes (FOUP), avoiding the impact of manual intervention, ensuring the clean environment of the vertical furnace production process, and improving product quality.

Wafer box transfer and storage system StockerThe stocker equipment for wafer box transfer and storage system is mainly used in the semiconductor field, acting as a buffer for wafer boxes (FOUP) in the vertical furnace production process. The stocker equipment effectively solves the problem of mismatched supply and cycle time between the vertical furnace process and upstream and downstream processes, and it also realizes the fully automatic opening and closing function of wafer boxes (FOUP), avoiding the impact of manual intervention, ensuring the clean environment of the vertical furnace production process, and improving product quality.-

SemiconductorSemiconductor

-

-

Wafer Transfer System (WTS)

Wafer Transfer System (WTS)The system interacts with the customer's OHT system to achieve Foup input and output, uses a FOUP robotic arm to transfer and store Foups between different process stages, uses an internal Loadport to open and map Foups, uses WTS to transfer, combine, and separate wafers, uses mapping at three locations to confirm wafer status and compare data, uses a fixed BF to buffer 50P wafers, and uses PTZ to hand off to the cleaning robot. The top EFU maintains a micro-clean environment for the equipment, and the top ion bar removes electrostatic residue from the transport path.

Wafer Transfer System (WTS)The system interacts with the customer's OHT system to achieve Foup input and output, uses a FOUP robotic arm to transfer and store Foups between different process stages, uses an internal Loadport to open and map Foups, uses WTS to transfer, combine, and separate wafers, uses mapping at three locations to confirm wafer status and compare data, uses a fixed BF to buffer 50P wafers, and uses PTZ to hand off to the cleaning robot. The top EFU maintains a micro-clean environment for the equipment, and the top ion bar removes electrostatic residue from the transport path.-

SemiconductorSemiconductor

-

-

Equipment Front-End Module (EFEM)

Equipment Front-End Module (EFEM)EFEM stands for Equipment Front End Module. EFEM equipment seamlessly connects with various semiconductor process equipment (etching, PVD, CVD, cleaning equipment, etc.), ensuring automated wafer transfer and efficient wafer management in a clean environment. EFEM equipment has multiple interlocks to ensure the safety of personnel and equipment during wafer transfer.

Equipment Front-End Module (EFEM)EFEM stands for Equipment Front End Module. EFEM equipment seamlessly connects with various semiconductor process equipment (etching, PVD, CVD, cleaning equipment, etc.), ensuring automated wafer transfer and efficient wafer management in a clean environment. EFEM equipment has multiple interlocks to ensure the safety of personnel and equipment during wafer transfer.-

SemiconductorSemiconductor

-

-

Wafer Transfer Module (WTM)

Wafer Transfer Module (WTM)Wafer transfer platforms are an indispensable part of semiconductor process equipment. They primarily automate wafer transfer between different modules in cleanroom and vacuum environments. These platforms can quickly switch between atmospheric and vacuum states to meet system process requirements. This equipment is typically customized to meet customer process needs.

Wafer Transfer Module (WTM)Wafer transfer platforms are an indispensable part of semiconductor process equipment. They primarily automate wafer transfer between different modules in cleanroom and vacuum environments. These platforms can quickly switch between atmospheric and vacuum states to meet system process requirements. This equipment is typically customized to meet customer process needs.-

SemiconductorSemiconductor

-

-

Liquid Flow Measurement & Control

Semiconductor

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.