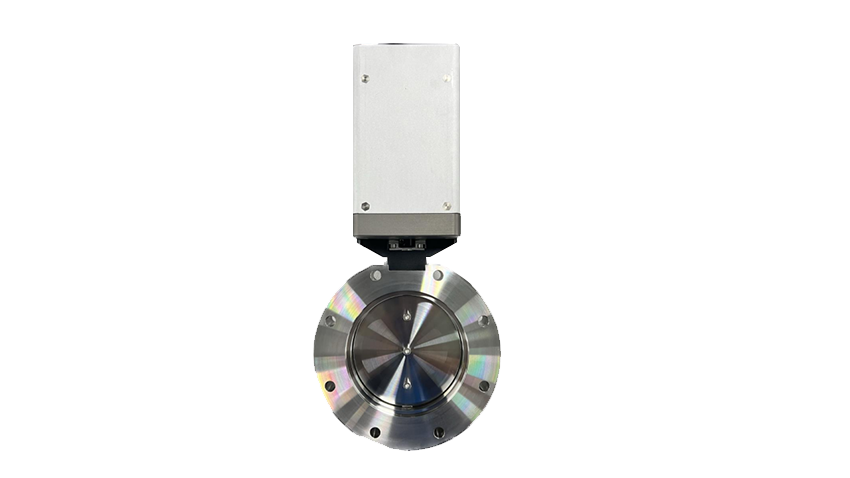

BV300 Butterfly Valve

Advantages

High Position Accuracy

Meet the Needs of Advanced Process Applications

High Pressure Control Accuracy

Customizable

Innovation

Dual Self Matching Pressure Sensing Technology

L-V-P Pressure Control Technology

Self-learning Technology

Advanced Servo Drive Technology

Application areas

Semiconductor-Integrated Circuit

Semiconductor-Advanced Packaging

Semiconductor display

Semiconductor lighting

Semiconductor-Microelectromechanical Systems

Power semiconductor

Compound semiconductor

Technical indicators

| Model | BV300 |

| Flange End Interface Type and Size | ISO-KF:DN40、DN50; ISO-F: DN63、DN80、DN100、DN160、DN200 |

| Leak Rate | 1 ×10E -9 mbar l/s |

| Pressure Range (at 20℃) | 1×10E -8 mbar-1.2bar (abs) |

| Pressure Control Accuracy | 5 mV or 0.1% of setpoint, whichever is higher |

| Sensor Input Signal | 0-10VDC |

| Material | Valve body/Valve plate: 316L/Aluminum; Seal: Fluororubber/Perfluoro |

| Position Resolution | 12800 (90° angle) |

| Response Time | Non-sealed type: switch 0.2S; Sealed type: switch 0.6S |

| Communication Interface | D-Sub, DB-25 Female, RS422/RS485, RS232, DeviceNet, EtherCAT |

| Power Supply Interface | D-Sub, DA-15 male, +24 VDC(±10%)@0.5 V pk-pk max |

| Vacuum Gauge Interface (Sensor Interface) | D-Sub, DA-15 female |

| Operating Ambient Temperature | 0 ℃ to +50 ℃ max. (Recommended <35 ℃) |

| Installation Position | Horizontal and vertical installation |

Note:

Butterfly valves are usually calibrated with voltage to the sensor signal at the factory.

The unit of gas pressure is specified as: Torr; mbar

Standard state is defined as: Temperature - 273.15K (0℃); Pressure - 101325 Pa (760mm Hg)

F.S. (Full Scale): Full scale value; S.P. (Set Point): Set point value

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.