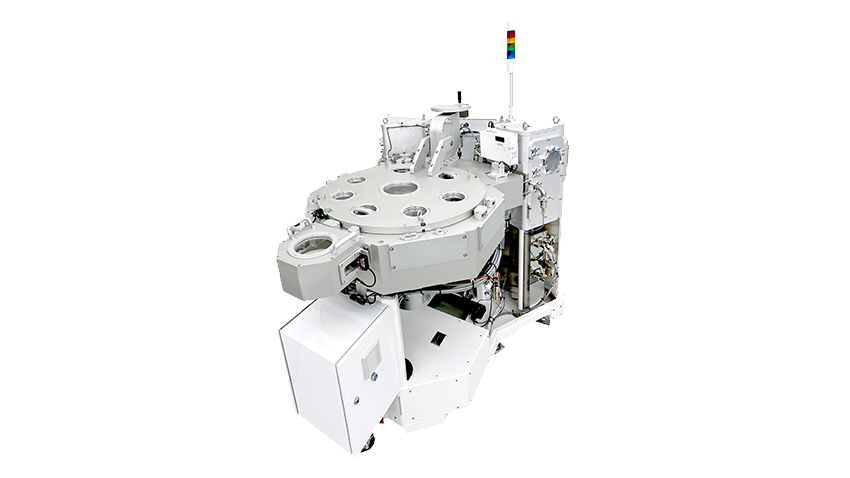

MX700 Wafer Transfer Platform

The wafer transfer platform is an indispensable component of semiconductor process equipment, mainly realizing the automated transfer of wafers in a clean and vacuum environment between different modules. The wafer transfer platform can quickly switch between atmospheric and vacuum states to meet system process requirements.

This equipment mainly consists of components used to transfer wafers between different process modules during the process. This system includes a front-end VCE (Vacuum Cassette Elevator) for loading wafers and storing cassettes (which hold 6-inch or 8-inch wafers), a platform vacuum chamber, a vacuum robot, a vacuum aligner, a cooler assembly, a wafer separation module (WSM), etc. It is used to transfer 6-inch/8-inch wafers. The equipment has multiple interlocks to ensure the safety of personnel and equipment during wafer transfer.

Advantages

Compliant with SEMI standards

The machine design conforms to SEMI S2/SEMI F47 and other semiconductor industry standards.

Customized

Custom-made according to customer process needs, to meet customer process film needs.

High repeat positioning accuracy

The repeat positioning accuracy of the vacuum manipulator is < ±0.1mm.

Status switching is fast and stable

The system can quickly and stably switch between vacuum and atmospheric states according to the needs of root process chip transmission.

Multiple detection sensors

The device is configured with multiple detection sensors to detect different states of the wafer, ensuring a stable and reliable transmission process.

Innovation

Dual transmission method

Depending on process requirements, it can achieve wafer individual transfer and simultaneous transfer of wafers and carriers.

Detect thrust ring offset

It has the function of separating/combining wafers and carriers, and can also detect carrier offset.

Position calibration

Calibration can be performed individually for the chuck ring position or simultaneously for the wafer and chuck ring positions.

Application areas

Semiconductor display

Semiconductor lighting

Power semiconductor

Technical indicators

| Cleanliness | ISO Class 1 |

| Wafer Specifications | 150mm/200mm Si |

| Wafer Specifications | 300mm Standard Wafer (Si) |

| Equipment Background Vacuum | <1Torr |

| Equipment Leak Rate | Transfer Chamber <15mT/min, VCE <2mT/min |

| Wafer Transfer Accuracy of the Robotic Arm | <±0.1mm |

| Wafer Transfer Pressure | 50mbar (Real-time pressure control according to process requirements) |

| PM Wafer Pick-up Temperature | < 600℃ |

| Vacuum Robotic Arm | Z-axis stroke 35mm, maximum reach 1010mm |

Related Products

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.