300mm wafer box transfer and storage system

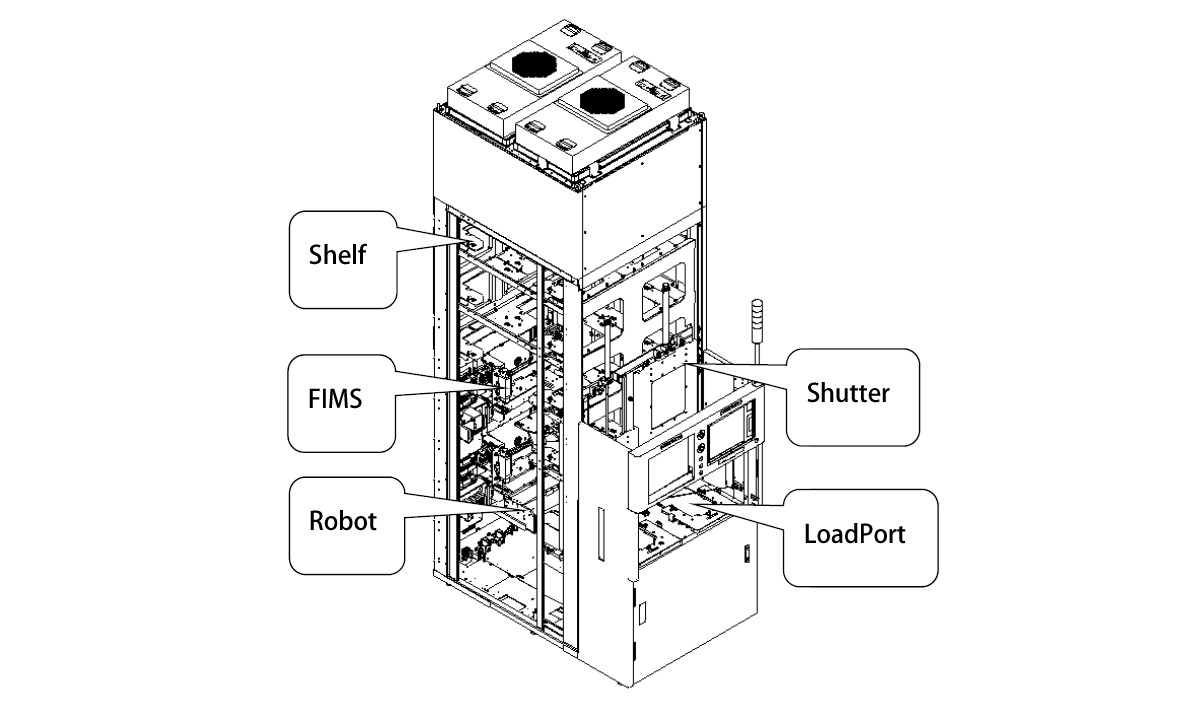

The 300mm wafer cassette transfer and storage system mainly consists of a wafer cassette FOUP loading system LoadPort, a wafer cassette storage rack Shelf, a robot Robot, a fully sealed FIMS, a pneumatic system, and an electrical control system. It realizes functions such as loading and unloading wafer cassettes FOUP, temporary storage, and wafer cassette FOUP switching. The wafer cassette FOUP loading system in this product is divided into two A/B positions to realize the loading and unloading of wafer cassettes FOUP. The wafer cassette FOUP storage rack has a total of 18 positions, which can store multiple FOUPs. The robot Robot is used for picking, placing, and handling between different positions. The fully sealed FIMS can realize the wafer cassette FOUP switching function and ensure the sealing requirements between the stocker and the process equipment.

Advantages

Multi-position storage

It can realize the temporary storage of multiple wafer boxes FOUP, to a greater extent meet the actual production needs.

Full process particle control

Throughout the entire process of robotic pick-and-place, temporary storage on shelves, and fully sealed FIMS switch box operations, complete particle control is implemented to ensure the product meets higher process requirements.

Strong compatibility

This product is suitable for various models of FOUPs from different brands and is compatible with different product types.

Innovation

High automation efficiency

It can achieve fully automated production and unmanned operation, effectively avoiding interference from human factors.

Fully sealed FIMS

Innovative structural form, stricter control of particles, a unique product in China.

Crane system interaction

Features interaction with client's OHT system for FOUP handling, including FOUP transfer and storage.

Application areas

Semiconductor Integrated Circuit

Semiconductor—Advanced Packaging

Semiconductor display

Power semiconductor

Compound semiconductor

Photovoltaic

Technical indicators

| Vibration Value | ≤0.3g |

| Particle Index | <10ea@0.02μm, <3ea@0.5μm |

| FIMS Nitrogen Purge | Reduce oxygen concentration in the FOUP wafer box to ≤50ppm within 4 minutes at a flow rate of 80L/min |

Related Products

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.