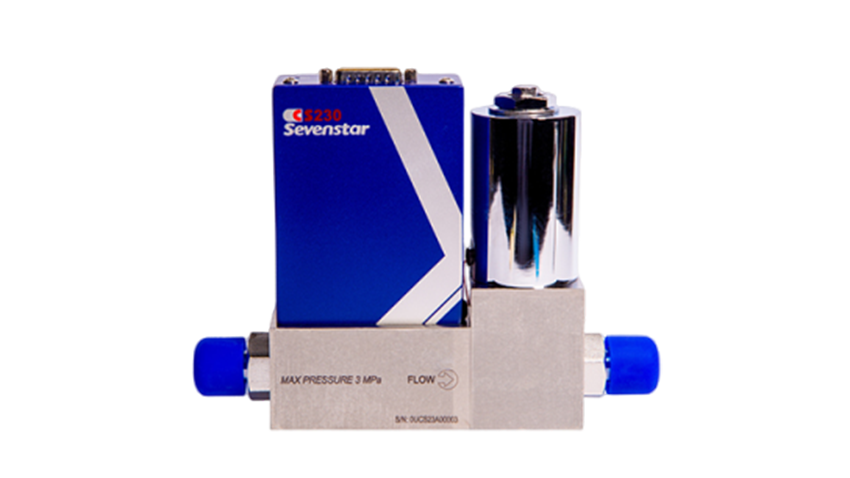

CS230A Thermal Digital Gas Mass Flow Controller

The CS230A product is a high-flow product developed by Hua Cheng Electronics, with a maximum flow rate of up to 300 SLM nitrogen and supporting both digital and analog control modes. The product uses a high-speed control algorithm to significantly improve the response time of the flow meter, with a high-speed response of up to 2 seconds to minimize system errors during use and ensure more accurate flow measurement. The product features low zero drift and low temperature drift, and supports DeviceNet and RS485 communication protocols.

Advantages

High Precision, High Stability

Using signal processing chips with fast conversion rate, low temperature coefficient, strong common-mode rejection ratio, and low power consumption, the product features high precision, high stability, and high anti-interference performance. The accuracy can reach up to ±0.8%S.P.

Low Zero Drift

Using a low-power sensor based on the principle of constant power, combined with software and hardware temperature compensation functions, achieves low zero drift. Without correction, the zero point ≤0.5%F.S., the temperature coefficient is less than 0.02%F.S./℃ (zero), 0.05%F.S./℃ (span).

Perfect Functions

Features auto-reset, alarm, soft-start, and delay functions, and is equipped with powerful free client software.

Innovation

Valve Control Technology of VCP

Valve control technology adopts a number of new achievements, collectively known as VCP technology. This structure has a small internal gas dead zone, fast valve response speed, and no hysteresis phenomenon. Using VCP technology can effectively improve the quality of gas mass flow controllers.

Constant Power Sensor

A novel constant-power sensor technology is adopted. This technology uses a method to maintain a constant operating state of the sensor, significantly improving multiple indicators such as system measurement accuracy and response speed.

Digital Sensor Compensation Technology

A digital sensor bridge balancing method is used, which can compensate for the sensor driving voltage with continuous voltage to improve the product sensor's suppression of temperature drift, enabling the product to withstand drastic temperature changes.

Application Areas

Clean Energy - Photovoltaic

Special Industry - Heat Treatment

Life Sciences - Environmental Protection

Life Sciences - Food Industry

Specifications

| ITEM | CS230 A | |

| Full Scale Range(N₂) | (50,100,150,200,250,300)SLM | |

| Accuracy | ±1.0% S.P.(≥35%F.S.)±0.35%F.S.(<35%F.S.) | |

| Linearity | ±0.5%F.S. | |

| Repeatability | ±0.2%F.S. | |

| Response Time | ≤ 2 sec | |

| Valve Rest Position | Normally Closed | N/A |

| Differential Pressure | (0.15~0.35)MPa(50SLM≤Flow<150SLM) (0.20~0.35)MPa(150SLM≤Flow≤250SLM) (0.25~0.40)MPa(250SLM |

50~100SLM: <0.02MPa > 100SLM: <0.05MPa |

| Temperature Coefficient | Zero:≤±0.05%F.S./℃; Span: ≤±0.1%F.S./℃ | |

| Max. Operating Pressure | 1MPa | |

| Max Pressure | 3MPa | |

| Zero Drift | <0.6%F.S. per year without autozero | |

| Leak | 1×10⁻¹⁰ Pa·m³/sec He(1×10⁻⁹atm·cc/sec He) | |

| Seal Material | Viton; Neoprene | |

|

Operation Temperature |

(5~45)℃ | |

| Input Signal | Digital: RS485 or DeviceNet or ProfiBus; Analog:(0~5)VDC or(4~20)mA | N/A |

| Output Signal | Digital: RS485 or DeviceNet or ProfiBus; Analog:(0~5)VDC or(4~20)mA |

|

| Power Supply | ±8~±16VDC or+14~+28 VDC | |

| Electrical Connector | D sub 9 pins male;D sub 15 pins male; DeviceNet male; ProfiBus | |

| Fittings | Compression Fittingφ6; Compression Fittingl/4";(available to Flow≤60SLM) Compression Fittingφ8mm(available to Flow≤200SLM) Compression Fitting φ10mm; Compression Fitting 3/8"; Compression Fitting 1/2";VCR 1/2"M |

|

| Weight | 2.6kg | 1.5kg |

Related Products

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.