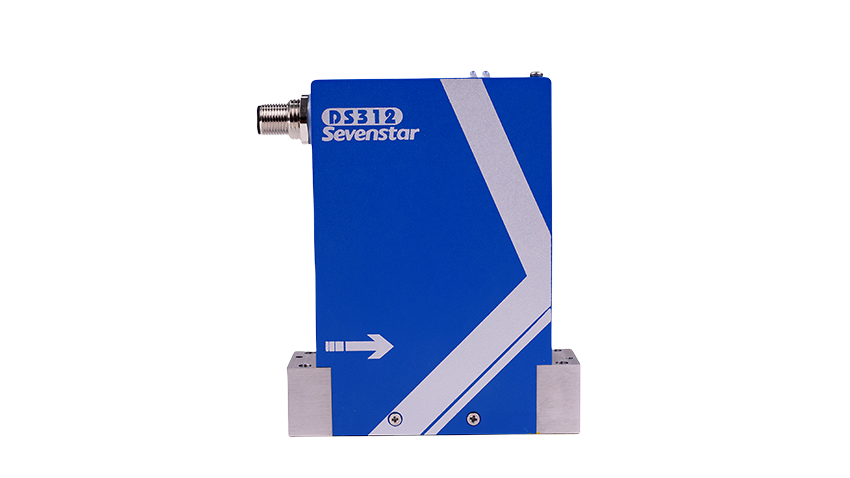

DS312 Pressure Type Gas Mass Flow Controller

Advantages

High control precision

Fast response

Low zero-drift phenomenon

Surface electrochemical polishing of deep blind holes and intersecting holes

Equipped with import pressure detection function

Innovation

Pressure sensing technology based on PTC (Pressure, Temperature, Channel)

Novel piezoelectric valve structure principle technology

High-precision piezoelectric valve drive technology

Material surface treatment technology that fully meets SEMI requirements

Application areas

Semiconductor Integrated Circuit

Semiconductor-MEMS

Power semiconductor

Compound semiconductor

Semiconductor—Advanced Packaging

Semiconductor display

Semiconductor lighting

Technical indicators

| Model | DS312 |

| Flow Rate Specification | 50~10000 sccm (DS312C) |

| 50~5000 sccm (DS312W) | |

| Valve Type | Normally Closed |

| Inlet Pressure | 240~450 kPaA, Flow Rate ≤5 SLM |

| 350~450 kPaA, Flow Rate >5 SLM | |

| Outlet Pressure | ≤3.3 kPaA (DS312C) |

| ≤13.3 kPaA (DS312W) | |

| Maximum Pressure Resistance | 1Mpa |

| Operating Temperature | 10℃ ~ 45℃ |

| External Leakage | 1 x 10 -11 Pa·m³ / sec He |

| Accuracy (including linearity and calibration system accuracy, etc.) | ≤ ±1%S.P. (≥10%F.S.) |

| Repeatability | ≤ ±0.3%S.P. (≥10%F.S.) |

| Response Time (flow rate reaches ±2% of the set point) | ≤ 0.5 sec |

| Standard Power Connector | DeviceNet Connector |

| Communication Protocol | DeviceNet |

| Standard Gas Path Connector | IGS-C, IGS-W |

| Material of Gas Inlet Part | F20 |

Note:

1. F.S.: Full Scale

2. kPaA: kPa, Absolute Pressure

Related Products

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.