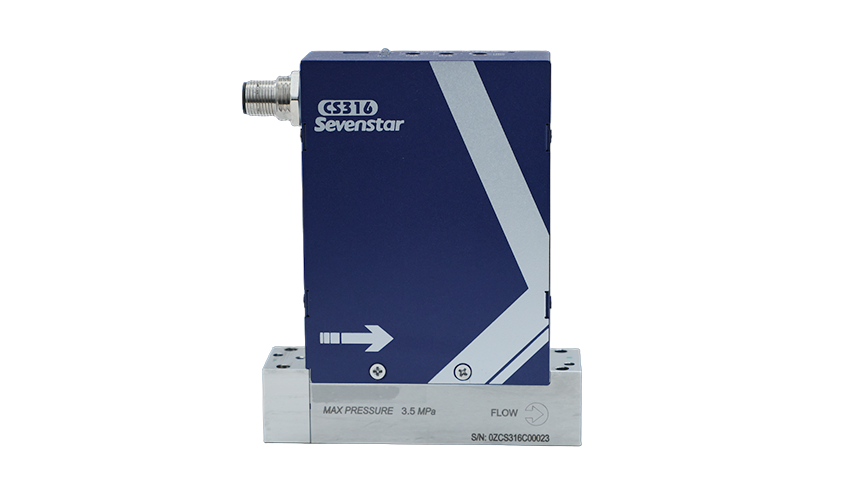

CS316 Thermal Digital Gas Mass Flow Controller

Advantages

Low Zero Drift

High Precision, Fast Response

High Stability

Semi-Level Surface Treatment

Innovation

Electro-Chemical Polishing

Constant Power Sensing Technology

Pressure Compensation Technology

Application Areas

Semiconductor - Integrated Circuit

Clean Energy - Photovoltaic

Specifications

| ITEM | CS316 |

| Full Scale Range (N₂) | (0~1,2,3,5,10,20,30,50,100,200,300,500) SCCM (0~1,2,3,5,10,20,30) SLM |

| Accuracy |

±1.0% S.P. (≥35% F.S.) (±0.80% S.P. (≥30% F.S.) optional)

±0.35% F.S. (<35% F.S.) (±0.24% F.S. (<30% F.S.) optional) |

| Leak | ≤5×10¹² Pa·m³/s |

| Response Time | ≤0.7 sec |

| Operating Pressure Differential Range |

0.05~0.35MPa flow rate ≤10SLM

0.15~0.35MPa flow rate >10SLM |

| Temperature Coefficient | Zero point: ≤±0.02%F.S./℃; Adjustment: ≤±0.05%F.S./℃ |

| Repeatability | ±0.2%F.S. |

| Linearity | ±0.5%F.S. |

| Pressure Transient Sensitivity |

10~100sccm ±(5%S.P+1%F.S. maximum) [3PSI/sec]

100~10SLM ±(1%S.P+1%F.S. maximum) [5PSI/sec] |

| Max Pressure | 3.5 MPa |

| Seal Materials | Metal Seal |

| Operation Temperature | (0~50) ℃ |

| Input Signal | Analog: 0~5V, RS485, DeviceNet |

| Output Signal | Analog: 0~5V, RS485, DeviceNet |

| Power Supply | ±8~±16 VDC (bipolar) or +14~+28 VDC (unipolar) |

| Fittings | VCR1/4 male connector; 1.125" C-type sealed connector; 1.125" W-type sealed connector |

Related Products

Contact Us

If you have any questions, please leave your detailed requirements information here, and we will be happy to serve you.